-

Posts

13 -

Joined

-

Last visited

-

Days Won

4

Posts posted by Philippe Bordelais

-

-

Dear colleagues,

What’s new in the ClipOne family!

The ClipOne are designed for the Steadicam and brushless gimbals users who want to reduce their rig weight without compromising use, quality or reliability.

New models, new designs and new Carbon French Flags!

For more information, videos and prices: www.abracam.eu

Philippe

-

SledX

Dear colleagues,

I want to introduce the latest Abracam product, the SledX™.

The SledX™ is a prototype of a gyro-stabilized handle designed to control brushless gimbals.

More information and video here

For those who will go to IBC, I’ll be there for some demonstrations.

Thanks for your attention

Philippe

-

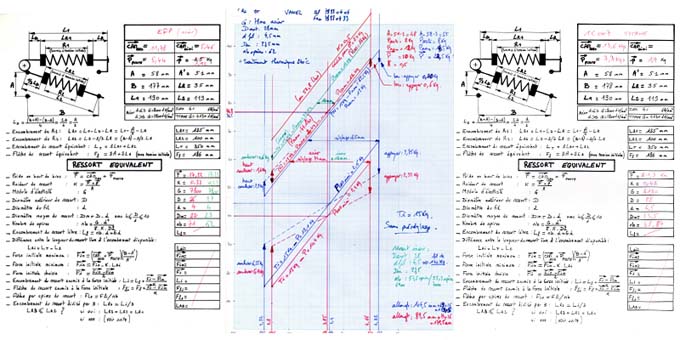

I embarked on this adventure in 1991, more than 24 years ago, already !!.

I don’ really know why? Passion? Defiance? Youth? Folly surely !

Today I wouldn't even think of doing it.

At that time I had neither CAD nor CNC to help me.

Here is my copy of the 3A arm (1992), totally homemade, only the spring covers are CP origin.

Manufactured in a single copy for my personal use and never marketed

Making successfully each mechanical parts at the first attempt seems unlikely to me. It’s harder than it seems.

I think I had to make about 3 arms before making one with success !!

But the most important difficulty isn’t there and can’t be seen:

The calculation of the springs, the iso-elasticity and their manufacturing, especially if you choose titanium springs, like me at that time.

You can’t have the same iso-elasticity quality and the same range of weights with steal springs.

I remember: :wub:

At least I advise to buy the springs (Steadyrig for example, if possible)

Philippe

-

Clip-one 2F

After introducing the Clip-one 3F

Abracam introduce the new Clip-one 2F

Only 70 grams !!

For a capacity of two 4" x 5.65" filters !!

Designed for use in extreme low weight situations.

For more information: info@abracam.eu

-

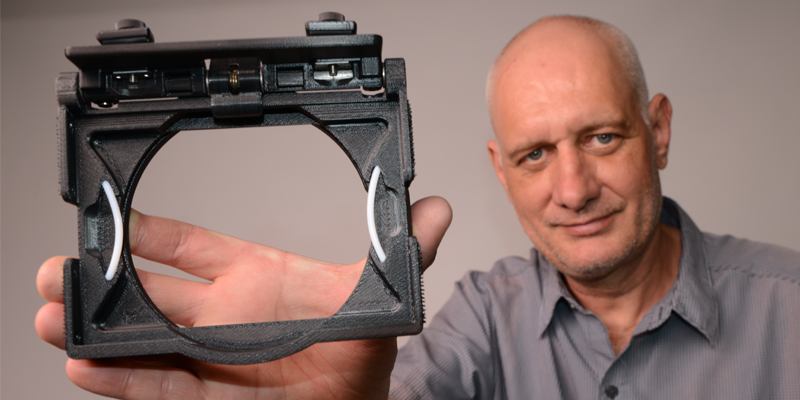

The Clip-one

Dear colleagues,

I want to introduce the latest Abracam product.

It is an ultralight Matte box which weighs only 150 grams for a capacity of 3 filters !!

The Clip-one is specially designed for the Steadicam and brushless gimbals users who want to reduce their rig weight without compromising use, quality or reliability.

It offers maximal functions for minimal weight and price, which makes it an innovating and unique industrially-3D printed product.

Up to 3 filters:

One 114mm circular filter (for example, a circular polarizer filter)

And two 4" x 5.65" filters

The Clip-one is also designed with a French flag adjustable support.

Lateral flags can easily be scratched.

Philippe

For more information: info@abracam.eu

-

Thanks Frederic,

Yes, mechanical tolerances are hard to obtain using the 3D printing production, from one machine to another, moreover from one process to another (Abs FDM, Pla FDM, STL, SLS…)

I agree Shapeways is probably not adapted in that case.

Concerning the Abracam 3D-Printed Products, my goal is to obtain the same optimal quality, and above all to guarantee the same constant mechanical tolerances, for each unit.

Here is a Batch of 10 ClampX StarliteHD Bridge 15x60mm, all impeccably alike:

I’d like to introduce the second model of the ClampX Series:

Philippe

-

1

1

-

-

Thanks Osvaldo

Very much appreciated!

The word workmanship leads me to precise the following:

For me, you have a good quality product if it successfully answers at least the 3 following criteria:

1) The functionality (what is it for and does it do the job?)

2) The design (my first step is ‘form follows function’)

3) The production (which production process?)

Concerning the DNR, I hope it fulfils criteria 1) and 2)

As for criterion 3) the DNR is a product made in aluminum and CNC machined.

We can all judge the quality of CNC production because we all have the CNC experiment and culture.

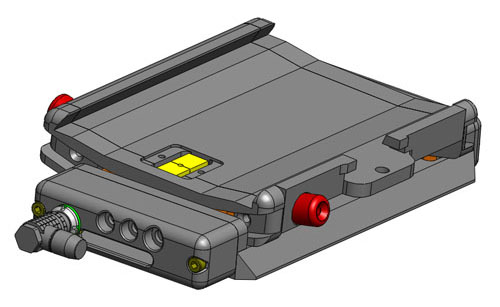

Concerning the ClampX, I also hope it fulfils criteria 1) and 2).

As for criterion 3) The ClampX is a product made in ABS and 3D printed, which makes a fundamental difference with the DNR. Hard to judge as we don’t have the 3D printing culture yet.

The only thing I can say is that I like to search the best quality for each of these 3 criteria.

Philippe

-

Dear colleagues,

I’ve been working for years around the 3D printing universe.

I’ve designed several prototypes: CIVA (2000), UVM (2011), DNR (2012), PTR (2013) and others, all have been studied using the rapid prototyping technology first.

On the way, I realized that this printing process can even be used in certain conditions for the final production. Of course, these conditions must be taken into account in R&D.

Everything is not possible!

But there are many advantages, and first of all: the creativity.

I intend to propose in the future several 3D printed products and to analyze the feedback.

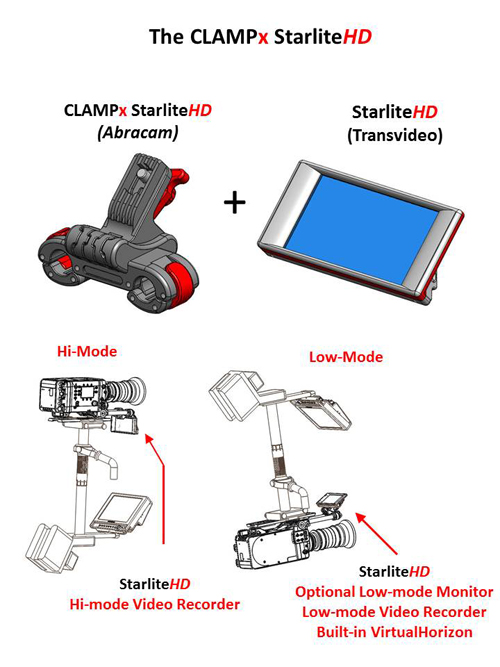

The first product I want to show is the ClampX for StarliteHD which is a support for the StarliteHD monitor from Transvideo.

It is the first small satisfying product I propose, because combining functionality with means of production.

The ClampX for StarliteHD is now available and will be shown on the Transvideo booth (11.F31) during the IBC 14.

For more information : www.abracam.eu

Cheers

-

How fast can you go to low mode? And why not in 1 second?

Has it ever happened to you that a Director asks for an ''urgent'' and improvised low-mode shot without having the time to adjust all your sled's elements for that?

If you absolutely need to be ready for this compromise, may I suggest this solution?

Abracam will introduce this product during the next IBC 2014 in Amsterdam on the Transvideo booth.

Hoping to have your feeling there.

The CLAMPx StarliteHD is a 3D printed product and the first of a future CLAMPx Series.

More information coming soon.

Philippe

-

1

1

-

-

This topic is the occasion to introduce one of my forgotten Abracam projects. I studied this Automatic Bubble for Steadicam during 2005.

A first prototype was manufactured in February 2006.

Technical specifications sought:

- Angular compensation: +/- 5°

- Compatible with the Steadicam plates standard.

- 1" thickness, 7" lenght, 5" larg.

- All in one: motor, electronic

- Plug and play

- Only 1 switch for the on/off and 1 button for the Zero calibration.(not the Concorde's dashboard)

- Hi- mode and Low-mode capacity.

- 15 Kgs load capacity

For several reasons, unfortunately, this project stays without suite...!

Best regards,

Philippe

info@abracam.eu

www.abracam.eu

-

7

7

-

-

I want to thank everyone for your interest

More information:

The Dock n Roll Price is 350 Euros + shipping

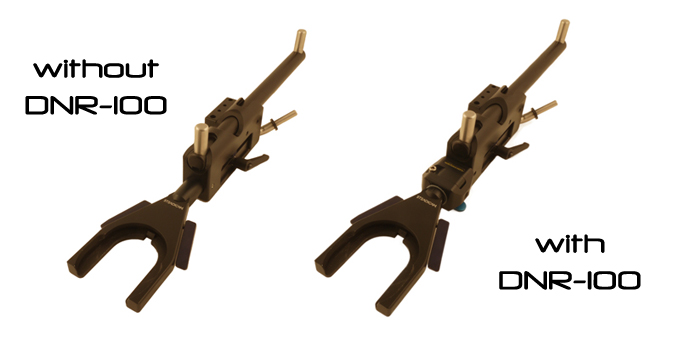

With or w/o the DNR, the length is similar (only > 0,5 inch)

With or w/o the DNR, the security is the same

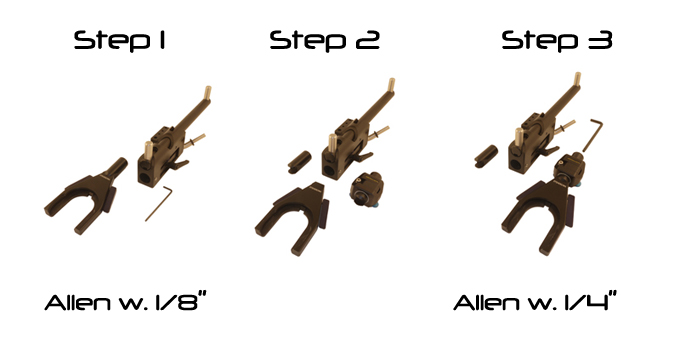

The DNR assembly is very simple, only 1/8’’ and 1/4’’ Allen wrenches are necessary.

The original screws are re-used

All the best

Philippe

-

2

2

-

-

Dear colleagues,

I am Philippe Bordelais from France, some of you may know me as I am the designer of the Freestyle 3D Rig from P+S Technik.

During the past year I decided to create a line of accessories for the Steadicam universe under the name Abracam.

My first product that some of you may already know is a Universal Vehicle Mount.

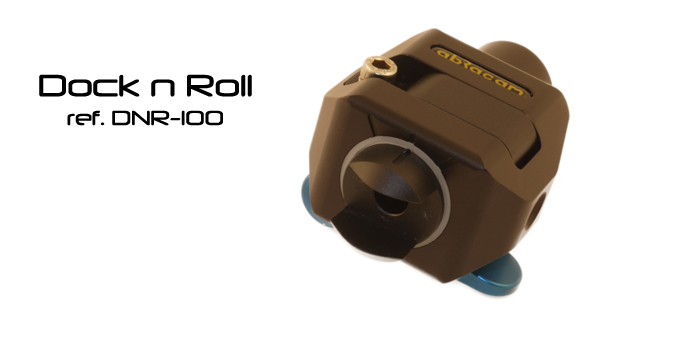

I will soon have a website with the complete line to show you, I will let you know when it will be online, today I am presenting my second product: the "Dock n Roll".

It is an add-on for the Jerry Hill docking bracket and it is compatible with both versions sold by Jerry Hill and Tiffen.

It was during CINEC 2012 in Munich that I introduced this new accessory

Has it ever happened to you that a Director asks for a static shot and says that you do not have the time to switch to tripod?

Has it ever happened to you that a DoP asks to hold a specific framing for some time so that he can light the set and adjust camera with the image he wants?

The Dock n Roll allows to do that, by precisely choosing a framing while keeping your Rig securely locked on your docking stand.

The Dock n Roll is designed with Teflon bearings which comes also handy when you want to quickly estimate your fore and aft balance while building your rig.

It is extremely useful when you have several camera accessories you need to add to a setup and in particular with beam-splitter 3D Rigs that uses 2 cameras and are often difficult to balance.

The DnR on BETZ TOOLS' booth during CINEC 2012:

The DnR on TIFFEN's booth during CINEC 2012, picture by Garrett Brown:

I have a batch of Dock n Roll available and ready to be shipped now.

Please get in touch with me for more informations: info@abracam.euCheers

-

8

8

-

-

This is a pretty crazy story!

As I work around Steadicam developments since many years, I have been approached by Amak for the preparation of a 3D movie starting end of last September.

Because of post production issues, they asked me if I could develop a special sled that could carry 2 SONY 900R and the 3D module.

This was challenging and I started to work on this!

With the help of Alain Derobe, a famous 3D DOP, I tried to find technical solutions to mix Steadicam and 3D technologies.

One of the main difficulties is to regulate the distance between the camcorders from 0 to 5? during the shot, without compromising the balance.

Also, the 3D module must weight around 4 kgs instead of 10/15.

I was quite often turning around solutions and would have loved to find some help and discuss with someone.

During my design process, I was not sure to make it successfully until the first tests, but finally everything worked perfectly during the movie. Fortunately because the shooting conditions were similar to the traditional Steadicam shooting.

Now that I see the pictures of Julian?s work, I simply can?t believe it!!

Of course the second vertical camera must be under the gimbal unless you have very lightweight cameras.

In this configuration, my system can support cameras up to 8kgs each. (Sony HD combos, RED, 235?)

For running the 2 focus motors parallel, I used the C-Motion system with the new 3D software protocol.

The cameras translation is motorised too, without influence the sled balance.

I suppose Julian has affected left eye to the vertical cam, as I did also, to have a better monitor?s visibility, which is the opposite of a standard 3D module.

This brings an additional work on post production: not good for the steadicam reputation as always !!!

Best,

Philippe Bordelais, Abracam Sarl

Garfield Mount Wanted

in Steadicam Marketplace - Wanted

Posted

Are you familiar with the Universal-Vehicle-Mount from Abracam?

Philippe