-

Posts

50 -

Joined

-

Last visited

Posts posted by Michael Nelson

-

-

I will ad in another vote for Janice's plate. I got mine a few days ago and am very pleased!

-

I have a shoot in downtown Saturday evening and need a bartech kit and an sd transmitter/ receiver kit. Is anyone able to rent them to me?

-

Hi Michael

Baer -Bel sell them at http://shop.strato.de/epages/61417979.sf/en_US/?ObjectPath=/Shops/61417979/Products/%2275%20Plus%20Motorrod%22

Good luck

Louis Puli

Is this the correct rod that I need? I can't tell from the information provided on the webpage.

Buy it from Pro, tap your base plate, good to go!

Thats what I did for my old sled, its a 10 min job.

Do you have a link for where I can get this?

Get it here. I think that this is what I will do

-

Sorry I didn't follow up with this. I am actually no longer working with that vest as it was owned by the studio. I am not sure what the status of the vest is with regards to the creaking. I continued to clean it for a few weeks after posting the question and then ended up moving out of state ad not using the vest anymore. Sorry for the unanswered question!

-

Honestly I doubt that you will hear back from MK-V

I am getting the feeling as well. I have heard so many MK-V customer service complaints and it's really too bad. I'm hoping someone with an MK-V can shed some light here though. I have much more faith with the members of this forum!

-

I just recently got a used MK-V evolution (very excited!) and I'm wondering what others have done when it comes to mounting accessories like a small on board recorder to the bottom cage or my Marell digital level for my monitor. I currently have the sliding Anton Bauer battery mount on the back and a fixed Anton Bauer mount on the front side of the cage. Does MK-V sell the small clamps that attach to the rods of the cage separately? I've emailed MK-V but they have not got back to me yet. Thanks!

-

Still looking! Money ready!

-

I'm looking for a place to find a replacement iris rod that attaches to my baseplate like this one:

I emailed MK-V already but I thought that I would ask here while the email marinated with the MK-V.

-

Oh, man! I loved these things! The vest should be made from an old life jacket!

-

Thanks for everyone's reply. I will be scheduling an appt with Robert Luna for the end of the week!

-

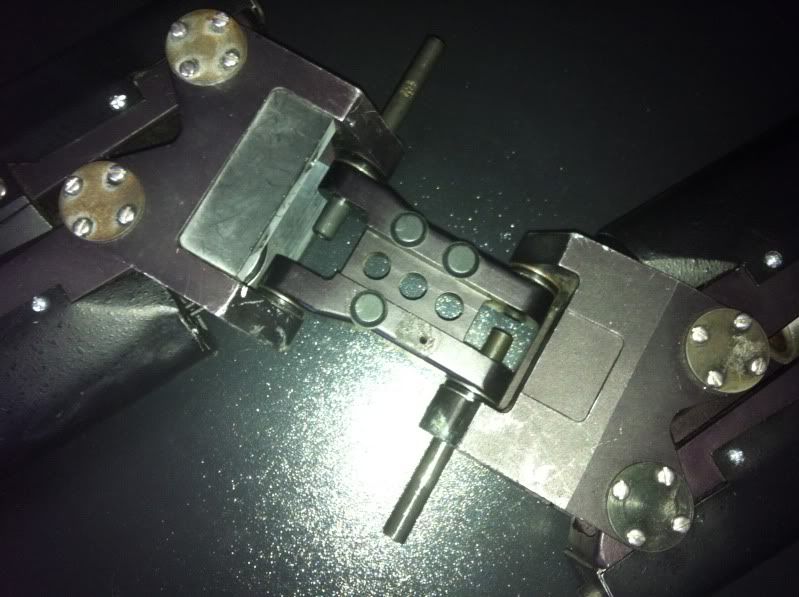

I did find these two hex screws and gave them a little tighten and it holds the pins in place and doesn't limit the functionality of the arm. What so these two screws do specifically?

-

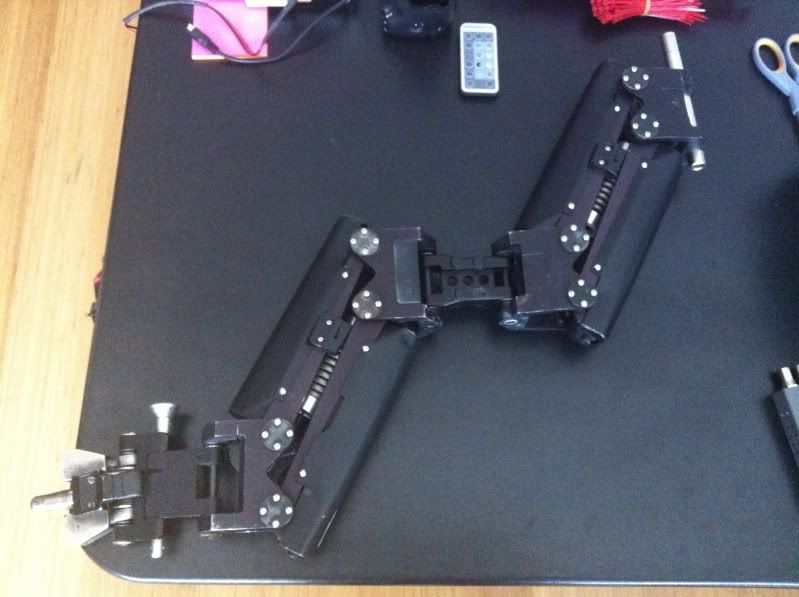

I have a question about an arm I have here. Take a look at the 3 pictures of the arm and you'll see that in the 3rd picture, the pins that hold the arm sections together are able to slide up and down fairly easily. They seem to be only help in place through the tension in the arm. This doesn't seem right at all and I'm wondering if some kinds of caps are missing to hold these pins in place.

-

Hello everyone! I would like to buy a Bartech kit (analog or digital) including Transmitter, receiver, motor, power cables, direct link cable, additional gears and focus wheels.

If you or anyone you know of is selling, let me know!

-Mike Nelson

nelson.michael.t@gmail.com

(720)220 - 1665

-

The chest plate on my Ultra 2 vest, namely the metal section that slides to adjust the length of the vest, squeaks and creaks when it's under load. If I clean it with a light soap and water, the creaking stops, but is back after a few days. Should I get some type of lubricant to stop the creaking for longer durations?

-

after not setting down the rig (50-60 lbs) after about an hour

There is your problem.

There's very limited chance to set it down during our show. We're getting it worked through about where to put a docking bracket in our small studio so I can rest it when for the few times it's not needed. It is a sort of "trial by fire" to get things fitting right and properly balanced.

-

So I wanted to update my post from a few days ago. I've been playing around with my vest and trying to break down what might be causing the lower back to tire more/ less quickly. I've been manipulating everything on the vest one at a time and listening to my body to get really comfortable for long periods of time. Today I changed 3 things and had a very good, fatigue/pain free day.

1. I made sure the lower back pad sat directly on the small of my back. When it's too high, I definitely fatigue quicker. So it rests directly on the small on my back and the straps wrap right across the "love handles". Not too low, on my hips and not too high where my lower back gets now support.

2. Most of my lower back fatigue started on the left side of my lower back so I though I might be leaning slightly on way or another. To try and correct this I used the T-wrench to let the arm tilt to the right a little more (at the socketblock) This adjustment definitely re-balanced the weight evenly across my lower back.

3. I tightened up the lower back buckles fairly snug to make sure the top front of the vest stayed snug on my sternum and didn't hang off my body too much. This relieved some of the pressure being put on my left shoulder and now it is much less sore.

Good to say that I feel great and it's a nice way to welcome in the weekend!

-

I find that initially my back is fine, very comfortable. However, after not setting down the rig (50-60 lbs) after about an hour my back fatigues and slowly starts to turn into pain. Similar to doing a wall sit (although in the back and not my legs) where its easy at first, but after a while, the muscles ache and then it builds into pain. This pain back is alleviated when I put the rig into the resting position and is gone in a matter of seconds.

I believe I have the vest fitting correctly, not much weight on my shoulders, the rig is balanced so it floats in front of me while standing in a comfortable position and I'm not leaning one way or another.

Is this a matter of building up the lower back muscles and building up tolerance or is this type of fatigue/pain the type associated with something being incorrect?

On another note. I occasionally get pain in my upper left shoulder. (The same muscle that someone would massage with their thumb when they give you a stereotypical "neck massage") This pain is alleviated by stretching my arm straight down or lifting my right shoulder up to bring the padding off of my left shoulder. I thought this pain might be brought on my vest sitting crooked and putting pressure on the one shoulder but I have had people look at the way the vest fits me while in an operating stance (hands on rig, looking at the monitor) and they say it's straight. Some days it's no big deal, and others it can become uncomfortable. Reasons why I would have this pain

-

Mike I feel your best option is to build your own vest using a leather belt and some shoe laces... maybe some duct tape as well for added rigidity.

And the secret to getting jobs with you brand new custom vest is to spray paint it neon pink with purple accents!!! :P

I see there letting anyone in this forum nowadays! Thanks for the advise, Mr. Blackman

Hi Michael,

It seams that you did the right first couple of steps. Taking the workshop etc.

So you are at the next step... buying equipment or at least starting to.

I would suggest to buy a new Vest that is build for you and your body type and fits properly from the get go and by pass the used market on that.( If that's what you really want to do for a living). It's like buying somebody's old sneakers (but that's just me and many will jump in and refute it). I know several ops that still own there first vest and still use it on a daily bases, Colin Anderson comes to mind. Usually the number of rigs somebody owned is considerably higher then the number of Vests. Yes it will cost you $4-5K but that's it, you spend it once and you might not buy one through out your carrier (exempt for the obligate service, repairs, etc.). I might still own my first PRO vest if it hadn't been for the break in... oh well.

I personally started with an original 3A that I had access from the local rental house (Thanks DEnny Clairmont) and later used a master for practice and on my first workshop. That's were I developed the dislike for that style of vest and the sweat that came from other ops... having to basically start from scratch adjusting the vest every single time I wanted to get into the rig.

After the workshop I developed the contacts to have access to other ops' gear. Getting the whole rig for practice was never the problem, it was always the Vest that was the hick up. Either I couldn't get it or I was not allowed to change anything on it. Even just turning the socket block over was a big deal to most ops... that's how I changed how I operated... I used to be goofy foot... (As I found out on my first work shop).

I am still baffled that I was able to talk Charles or Colin into letting me borrow theres... And stunned that Chris Haarhoff offered and let me use his for several shoots after mine was stolen to bridge the gap until my new Vest was build....

Anyhow...

As soon as I had the possibility and ability i went in for George to measure me up... and haven't looked back since.

That's what I suggest to newbies when they ask me. And I have yet to get a complained from the guys that did as I suggested... But I am getting a lot of : Oh I should have listened to you! When they didn't... Every time.

You can spend your money twice by buying a beat up used one and about a year into it for a brand new one or just skip the first step... It never fails. And if you decide to sell it in a years time you still get most of your money back.

Your call.

Just my two cents.

Erwin

Thank you very much for the advise!

-

I know the one you are talking about...I think they used something that was intended to split 1/4" jacks and just replaced them with LEMO plugs. I usually velcro this one to the bottom of my top stage just behind the post.

-

I attended a workshop last March in Lake arrowhead and it was very beneficial. I got to try all of the vests steadicam makes there, in addition to the master series vest I use from time to time here and a Klassen vest I've used. I LOVED the klassen. The owner who let me use it was about my size so it was close to the right fit. I would like to get one at some point.

-

I am a steadi-newb and have been working under a few different operators and a few different rigs. I'm in no place to spend the kind of money needed for a decent rig that will be a long term investment. I have a good connection for renting at a great price and will take advantage of it for as long as I can.

Would it make sense for me to invest in a vest for myself? That way I can get a consistent fit no matter what job I do and no matter which rig I happen to be using. Also, the vest will be able to stay with me for years as I work more and will integrate with a rig I may buy a few years down the road.

Thoughts?

-

No word on what they've decided. Last I heard they "can't make up their mind". So I have no idea what they will do. Concerns me a little with them being this indecisive. I'm optimistic, in my hopes for the job so we'll see how things turn out.

-

Every day I find that everyone is connected more than I realize. I guess gone are the days of making relatively anonymous forum posts. Someone around here always knows whats going on! That being said I love the steadicam forum community!

-

On Tuesday I am interviewing for a full time position at a local TV station. I was recommended to the studio for the position through my mentor who is passing on the job for upcoming seasons. The steadicam experience I have comes from independent features and commercials, not so much TV. What are the major differences can I expect? Being tethered being the first big one I would imagine. I do have some experience being on a radio and communicating with a technical director and other operators from shooting live corporate meetings and such.

They will be using HD cameras (will find out the model on tuesday). For a rig, they have plans to buy a rig of their own. (which models they are looking into I will find out on tuesday) They are currently working with my mentor to decide which one to purchase. For upcoming rehearsals, I will be renting a rig from my mentor that I am fairly familiar with.

Any and all advise is welcome!

Adele

in Operating

Posted

Reminds me of her performance at the Grammy Awards. One shot, great stuff, I find it very relaxing and enjoyable!

http://www.youtube.com/watch?v=Zi_Se9ZP6-Q